How to Build A Residential Wine Cellar – Tips for Beginners

Residential Custom Wine Cellar Construction In Las Vegas

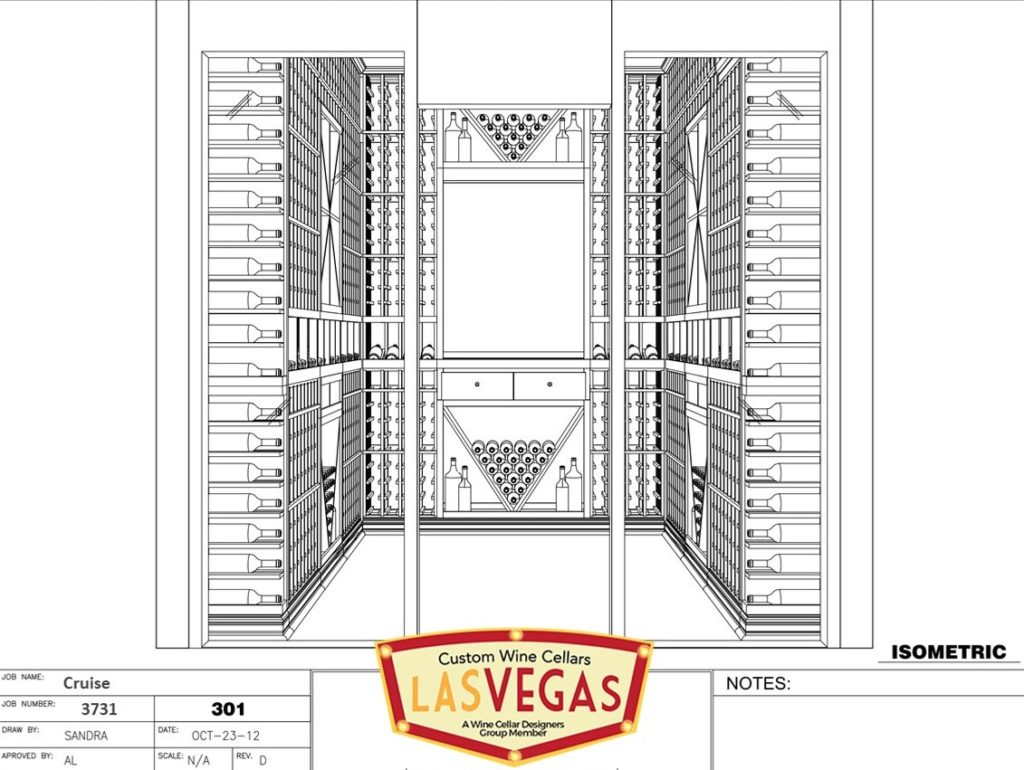

The aesthetics of the cellar racking is what most people think of when we talk about residential wine cellar designs.

How to Build A Wine Cellar – Tips for Beginners, Novice Contractors, Home Designers and Home Owners

Building a modern home wine cellar in Las Vegas is not especially difficult. If you are generally a handy person and comfortable with basic room construction techniques, you can do it yourself.

Having said that, there are several things to understand and get right. Simply attaching some racking and installing a cooling unit through a wall can lead to disaster. Sadly, we are often called in to rebuild residential wine cellars built like this.

Some people choose to hire a general contractor to build out their potential wine cellar room. Unfortunately, we have also seen many disastrous wine cellar installations built this way.

Specialist wine cellar builders usually know what they are doing and may cost more initially; however, they can save homeowners many dollars later by avoiding costly remediation work and possibly a ruined wine collection.

Whichever you choose, here is a general guide that should help you get it right.

How to Build A Residential Custom Wine Cellar – And Avoid Common Pitfalls

Break Your Project Down into Three Phases

- Designing Your Custom Wine Cellar

- Building a Wine Room Itself

- Installing the Wine Cellar Components

Designing a Residential Custom Wine Cellar

The aesthetics of the cellar racking is what most people think of when we talk about wine cellar designs. However, an experienced wine cellar designer will include specifications for materials, refrigeration system, doors, lighting, insulation, and much more.

They will consider loading factors, room size, traffic, whether walls will be glass, inside walls, outside walls, local climate, and provide a detailed design drawing including the specifications and costs of equipment. They will do this as well as specifying and visualizing racking type, capacity and the type of wines to be stored.

Even if you do it yourself, you are much more likely to be successful if you start with a professional residential wine cellar design. Moreover, given that good wine cellar designers will provide a design for free you would probably be crazy not to get one.

Building the Wine Room

Building the room includes preparing the floor, walls, and ceilings. It involves running the drain lines and ducting for your refrigeration system, running your electrical and lighting lines. Laying floors, insulating, applying a vapor barrier, and finishing the walls as well as the ceiling. Installation of any overhead lighting is usually considered part of the build out as well.

Your own experienced wine cellar contractor and electrician can be used for this part of your cellar construction. Using a contractor that says he has built wine cellars before does not guarantee that you will get a room constructed correctly. Therefore you, and they, usually need to be educated on how a wine cellar should be constructed. Building a residential wine room is NOT the same as constructing a regular room in a house.

Make sure your contractor builds your room to the CORRECT specifications.

Installing a Wine Cellar – Wine Rack Assembly

Installation, on the other hand, is installing the products needed to complete your room. Installing the refrigeration system, sometimes called a climate control system, installing the racking and installing a proper wine cellar door are all part of this process. Your contractor can install the door and wine racks, or you can have an experienced wine rack installer help you with this process. With an experienced installer, you know that the racks will be assembled correctly.

Note though that a wine cellar refrigeration system is a specialist, purpose-built, piece of equipment and is not the same as an HVAC system or window AC unit. The refrigeration system, if a split system or a fully ducted system, must be installed by a licensed HVAC contractor. If you are using a self-contained system, your contractor can usually install this.

Many other things can also be included in the build-out or installation phases such as adding rock walls, murals, LED ribbon lights and more. Depending on what you are installing, experts in each area can be hired to do various types of installations.

As you can see, building a wine cellar, or even wine closet can be done, however, there are many parts that need to be selected and installed just right.

Wine Room Preparation

Preparing your room to be a climate-controlled wine cellar is extremely important. If a room is not prepared correctly, you CANNOT cool the room without consequences down the road. A wine cellar with mold in it is not fun or cheap to remediate!

Without the proper vapor barrier and insulation surrounding your room with a tight seal, when a refrigeration system is installed, you run a high risk of mold and mildew forming inside the wall cavities and even the possibility that your studs or joists could swell or warp. Major home damage could occur.

Warning

DO NOT INSTALL A COOLING SYSTEM IF YOU HAVE NOT PREPARED YOUR WALLS, FLOOR, AND CEILING CORRECTLY!

Framing and Electrical – Custom Wine Cellar Construction

Build your walls using 2 X 4 or better using 2 X 6 inch studs. Remember, you will be maintaining a low temperature in the room, the extra 2 inches will make a difference. This is true also for ceiling joists.

Always follow the guidelines of local and state codes in your area. The thicker the walls, the more insulation you can fit in. Try to use 6″ studs on all exterior walls if possible.

Vapor Barrier

All walls and ceilings must be sealed with a vapor barrier. This means in new construction putting the barrier on the ‘warm side of the walls.’ To do this, you wrap the outside of the studs with your vapor barrier before attaching the outside wallboards.

On a room that is being remodeled, you will need to take down any existing wallboards on the inside of what will be the new wine cellar. With the bare studs showing, wrap the vapor barrier over each stud and into the stud cavity and back up over the next stud. If you choose to use this method, we recommend at least 6 or 8 mil plastic sheeting.

However, this is the way people used to build wine cellars, and we have found that over time is this is not the best method. Plastic sheeting can, unfortunately, be compromised causing the vapor barrier to deteriorate over time.

Custom Wine Cellars Las Vegas now recommends spray foam insulation (closed-cell) which does double duty as both the vapor barrier and insulation. It is much more stable and efficient.

Wine Cellar Insulation

Insulation is required if you want to cool your wine cellar, particularly when your wine cellar contains glass walls or doors. Make sure you use the most insulation you can for the thickness of your walls. R-13 or R-15 insulation can usually fit into a 2 X 4 wall while R-19 insulation might fit in a 2 X 6 wall. Do not try to pack in more insulation than is supposed to fit thinking it will make the insulation work better; it doesn’t. All cracks should be filled with expanding foam.

The old method of insulating and applying a vapor barrier in wine cellar construction was to put the barrier on the ‘warm side of the walls.’ Six- or eight-millimeter plastic sheeting was used. Wrapping the vapor barrier over each stud and into the stud cavity and back up over the next stud. This method is now outdated. Modern wine cellars have high-density CLOSED-cell spray foam insulation applied. This acts as a much more reliable vapor barrier and is also a significantly more effective insulator.

Also, note that a minimum of R-13 insulation should be used on any interior walls and a minimum of R-19 should be used on any exterior walls while R-19 to R-30 is recommended for the ceiling.

Be aware of the old methods used in cellar construction: standard fiberglass or rigid foam insulation. Also, take note that blown in insulation is not recommended as it can settle with time. However, it is essential that all walls and ceilings be insulated to keep the cellar temperature as even as possible during the summer and winter months or there is a great possibility all your wines will deteriorate.

Needless to say, we no longer recommend using any of these types of insulation at all.

Foam insulation

High-Density CLOSED-cell spray foam insulation is now the method of choice. When using closed-cell spray foam, it can take the place of both the plastic sheeting vapor barrier and regular insulation.

Custom Wine Cellars Las Vegas recommend closed-cell foam for all wine cellars, particularly in the Las Vegas area. It not only acts as a vapor barrier but can supply significantly better insulation in the same amount of space as older types of insulation.

The closed-cell foam will probably cost more to purchase and have installed; however, because of the much better insulating factors, it will save you money in the long run. You will pay for this product once but save on your electric forever and have less chance of vapor barrier failure. Keep in mind if you are using spray foam insulation you will need to run any electrical wiring through a conduit before the insulation is installed.

Here are our depth recommendations for closed-cell spray foam insulation:

- a minimum of 3 inches in any interior walls

- a minimum of 5 inches in any exterior walls

- a minimum of 5 inches in ceilings

- also, if the floor is above ground and not on a cement slab, a minimum of 5 inches in the floor as well.

Learn more about using spray foam insulation in Las Vegas homes.

Floors

Reclaimed Wine Barrel Flooring

If your floor is on a concrete slab, you will still need to add a vapor barrier before you add your wine cellar flooring. We recommend a product called Bostick’s MVP4; this product goes onto the concrete with a trowel. Once dried your flooring, such as reclaimed wine barrel flooring, can be laid. MVP4 can usually be found at your local hardware store.

If your floor is above ground however, you need to prepare the floor the same way you would your walls and ceiling. In this case, adding wood studs and a vapor barrier with insulation. You will then need to add at least a ½” plywood base before laying your flooring.

Consider Wine Barrel Wine Racks and Flooring for Something Special

Many things can be used to cover your floors. Slate, marble or vinyl tiles, even a cork floating floor are some options. Be wary of hardwood floors as they can sometimes warp in the higher humidity of a wine cellar UNLESS you are using a reclaimed wine barrel style of floor.

The wood from wine barrels that have previously held a liquid has already expanded and contracted during its former use. Therefore, it holds up well in wine cellar conditions. Reclaimed wine barrel flooring is available in a tongue & groove material and is laid just like a regular wood floor.

NEVER USE CARPET IN A WINE CELLAR. Carpet will cause mold and mildew to grow in the cool, damp climate conditions of a cellar.

As with the wall coverings, flooring is typically chosen to match the overall décor of the cellar as well as the rest of the house.

The flooring should always be applied to a level surface and keep in mind DO NOT apply trim, baseboards or moldings to the floor where the floor meets the wall anywhere your racks will be placed. Moldings will be installed on your racks once they are in the room. Any baseboards on the wall before the racks are installed will prevent a close fit for the racks.

A new product offered by Custom Wine Cellars Las Vegas is a coating of stone. Limestone from France is sprayed onto the wall surface, and hand carved to look like the stone of your choosing. This will give you the feel of a real underground cave.

Be sure any whole house HVAC vents are removed from the floor or ceiling. Any existing HVAC vents should be permanently sealed. Contact your HVAC contractor for advice.

Installing Special Features

Lighting

Commercial Grade Wine Cellar Lighting

In most instances, a recessed ceiling light is used in the ceiling of the cellar. This type of lighting will not get in the way or interfere with the bottle storage in the racks. When using recessed lighting, it is essential to use ‘airlock recessed can lights.’ Check to be sure they are IC rated (insulation contact) so that the vapor barrier and insulation can be wrapped around the can.

If your room is large enough, you can also use a hanging light or track lighting. Again, wherever the electrical components are in the ceiling, be sure the integrity of the vapor barrier is not compromised.

Any ceiling lighting must be a minimum of 16” from the wall if you are using single deep wine racks and 29 ½” for double deep racking. This is measured from the edge of the light to the nearest wall.

Whatever lighting you choose, try to stick to LED bulbs or lights that accept such bulbs. LED lights produce the least heat and are recommended for all wine cellars. Your lights can be put onto dimmer switches to allow the lighting to give you the desired ambiance.

Also popular are various display lights to accent different areas of the cellar, for instance, LED low wattage flex ribbon lighting is commonly used above any display rows in a wine rack. Make sure to choose a waterproof variety. The ‘warm white’ color looks the best in a residential wine cellar. A bright white color would be more appropriate in a commercial location where there are already bright lights outside the cellar.

Wine Cellar Doors

Custom Wine Cellar Door Designs

Note that this section is titled ‘Wine Cellar Doors’ not just ’Doors.’ Wine cellar doors are specifically made for a wine cellar. They should be solid wood and/or insulated, but a door that is LVL constructed is the best when looking for a wood door.

LVL doors are made to withstand the higher humidity levels of a wine cellar and will be less likely to warp in those conditions. Any solid wood wine cellar door should be exterior grade and at least 1 ¾” thick.

Sealing Components of the Door

Any wine cellar door should include good quality weather stripping for an airtight seal and must have a method of keeping the air from escaping below the door.

The bottom of the door is the most common place that air will escape from a wine cellar. You have gone to a great deal of trouble sealing your walls, floor, and ceiling. Be sure to add an automatic door bottom to your wine cellar door to complete the seal.

Door Insulation

When installing your door, it is advisable to use a can of closed-cell slow activating foam to fill the gap between the jamb and the rough opening before installing your case moldings.

Any glass in your door must be a dual pane tempered glass with a minimum of ½” gap. This will give you the most insulation factor and will help to prevent condensation from forming.

Iron doors can also be used on wine cellars. Be sure that if an iron door is used that it includes high-density foam insulation inside the door, dual pane glass, and weather stripping.

Climate Control Systems or Refrigeration Systems

Climate control systems, cooling units, refrigeration systems, chiller, whatever your terminology, the system you choose to cool your wine cellar is of utmost importance.

It is best to decide which system will be installed in your wine cellar at the beginning of your project so that the correct electrical lines and drain lines can be run during the construction process.

If installing a split system, you will also want to run your copper lines before the walls and ceiling are built. Get advice and help from a wine cellar specialist who knows about the many types of systems on the market when ordering your unit. Purchasing the wrong type of unit can end up being costly and disappointing in terms of noise and performance.

Whether you choose a self-contained ducted system, through the wall unit, a ducted split system, or a ductless split system, you will need a drain line running from the evaporator to a drain or container.

Every unit will need at least one dedicated electrical outlet, sometimes two. On an electronically controlled split system, the dedicated outlet is near the evaporator. The compressor could be in a large mechanical room, a garage, or even outdoors.

Installation of the Wine Refrigeration System

Some self-contained systems are meant to go through the wall and vent into another heat and air-conditioned space next to the wine cellar. This space should be at least 2X the size of the wine cellar.

There are even a couple of systems that will work by going through the wall to the outdoors. However, if you intend to vent to the outdoors, you must use a unit that is specifically designed for the extreme outdoor weather conditions.

Some self-contained systems can be ducted to and from the cellar. This will allow you to put the unit in a small space next to the cellar and duct the air from another room with a larger air flow capacity, to and from the cellar.

No matter where you put a self-contained unit, you must have access to it. You cannot build it into a wall space and seal the wall. Just like your home AC unit, your wine cellar refrigeration device will need periodic maintenance. Also, keep in mind that most units must be placed in an area that will not be exposed to extreme heat.

Ductless and Ducted Split Wine Cellar Systems

If you decide to use a split system, you can choose from a ductless split system or a ducted split system.

A ductless split system has an evaporator coil that is placed inside the cellar on the wall or ceiling, depending on the style that works for your cellar. It is connected via two copper lines to the compressor that can sit either in another large room inside the home (at least 2X the size of the cellar) or outdoors.

With a ducted split system, the evaporator coil is placed indoors in another room and is ducted to the cellar, usually through the ceiling. Both the intake and return duct are necessary. The evaporator is then connected to the compressor via two copper lines. Again, the compressor can sit in a large indoor room such as a mechanical room or garage, or it can sit outdoors.

Choosing the Right Type of Wine Refrigeration System

RM2600 Wine Refrigeration System Example

Refrigeration units vary by manufacturer and what each type of unit can do. Some have optional humidifiers that can be added though most help to control the humidity in a room but don’t add more.

Climate is One of the Factors to Consider When Installing a Wine Refrigeration System

Sometimes, particularly in Las Vegas, adding humidity is needed. This is because you live in the middle of the desert which is a VERY dry climate.

If your wine cellar has 2-3 exterior walls, you may need a system that also has a heater attached. For those days where your cellar could get too cold, it will automatically add heat to bring it back to the proper temperature.

If your compressor will sit outdoors and the temperature reaches 40 degrees or colder, be sure to check into adding a low ambient kit. This will keep the liquids flowing properly during cold weather.

When choosing a refrigeration unit avoid looking at only the price. Some refrigeration units have multiple fan speeds while others are bare bones with no extras at all. Find a unit that works for what you need it to do. Each wine cellar is different. Many factors determine the size of the unit you will need.

Many manufacturers simply tell you the cubic feet that a unit is supposed to refrigerate. What they sometimes do not tell you, or factor in, is the variances in each cellar. This includes things like the R-value of your insulation, the type of door you are using, if your walls are interior or exterior, and many other variables that have a bearing on the BTUs needed to refrigerate your cellar. For instance, a cellar that is 500 cubic feet may take one unit while another cellar of the same size may require a different sized unit due to the installation factors.

A Wine Refrigeration Expert Can Help You

Choosing a unit to cool your wine room is where you should consult a wine cellar specialist. They should perform a heat load calculation, and this will determine the precise size of unit appropriate for your wine cellar.

Getting the right size and type of refrigeration unit, thinking in terms of the complete system, is critical to ensuring efficiency and to avoid problems such as breakdowns, humidity, and mold. Just guessing which cooling system to install is not smart and unfortunately where many people go wrong. The cooling system should also come with a maintenance agreement. Wine cellar refrigeration systems require regular servicing to avoid breakdown and to keep them running efficiently.

Wine cellar specialists also have the knowledge and years of experience with many types of cooling units to know which units work best in different conditions and climates. Las Vegas is very dry and hot for extended periods in the summer, and occasionally in the winter it can drop below freezing. It would take you hundreds of hours to learn everything about the cooling units on the market today. A wine cellar specialist is knowledgeable and up to date about all the best units available.

Wine Racks

Quarter Round Display Wine Rack

Deciding on the style of wine racks you want can be a daunting experience. Just in the wine rack kit category there are several different styles.

Traditional, stackable, double deep, on top of which each manufacturer makes their racks slightly differently. Moreover, we are just talking about wood wine racks; there are also metal wine rack kits.

For specific details on what to look for when choosing your wine racks, follow the link to our blog and an article specially written to offer you more detailed help.

Types of Wine Racks

The most common types of wine racks are wooden wine rack kits, wood custom racks, modular racks, and metal racks. At Custom Wine Cellars Las Vegas, we offer wood wine rack kits in Traditional, Stackable, Double Deep and a Commercial line.

Several manufacturers offer modular racks. Vintage View metal wine racks are also a great choice. Wall mounted, floor to ceiling mounted, or free-standing metal racks are available as well as the new tubular style. You can view all these racks on our Wine Racks page.

Custom Wine Racks

Custom wine racks are just that, custom. They are designed and made specifically for you and your wine cellar.

We can create almost anything you or the design team, here at Custom Wine Cellars Las Vegas can dream up for your cellar. You can view a few of our past projects in our Wine Cellar Gallery.

Wine Rack Installation

How easy or complex your wine rack installation will be is determined by the type of racks you choose.

- Traditional Wood Racks

- Contemporary Wine Rack

- Metal Wine Racks

- Modular Racks

- Custom Wine Racks

- Wire and Pin Wine Racks

- Wine Racks for Storage Density

- Display and Label Forward Racking Solutions

- Bulk Storage Wine Racks

- Case Storage Wine Racks

- Combinations of the Above

Custom Residential Wine Cellar with Attractive Wooden Wine Racks

Here we have gathered together a number of tips which are typically not included in the assembly instructions for most traditional, stackable, double deep kits and custom wood racks. If you are not assembling the racks yourself, you can pass this information on to your installer.

- When taking off the shrink wrap from the pallet that your boxes arrive on, look for a yellow envelope. This will contain your instructions and hardware for assembly.

- Do not open all the boxes at once. You do not want to mix up the parts from one rack to another. Sort the boxes. They are usually labeled by the elevation on your design drawing, A, B, C, etc.

- If you have curved corner racks, begin with them and work out along the wall. As each rack is assembled, set it in place but do NOT attach it to the wall yet.

- If you have an upper section and a lower section, be sure your lower section is level before adding the upper section.

- Wait until all racks are in place before attaching the front stabilizers. This way you will be sure to place them so that each one is level with the next rack.

- When attaching your racks to the wall, use a stud finder to shoot a nail from your nail gun through the back stabilizer into the wall stud. Be careful not to shoot nails near any electrical lines or drain lines.

- If you find a long piece that is not molding but is somewhat three-sided, this is your corner filler. (Only included if you have square corners.) This will need to be attached as you are putting your racks in place.

- There are two basic moldings, one is the 1 ½” molding, and this is the base or Toe Kick molding. The 2 ¼” molding is for the crown. These will need to be cut to fit and the corners mitered at the correct angle. If you have a 2-step crown in your design, there will be two parts to your crown molding.

- If your racking has display rows:

- If you find a long piece that is L shaped, this is your light valance, if there is a light valance in your design. This goes up and behind the front of the display row. It will need to be attached to your rack while assembling it before you put the rack in place.

- You will also have a wider piece that has dados cut into it that will fit above the display row.

- You will have another long piece of wood that will need to be cut to fit that goes at the bottom of the display row. It does not have dados cut into it.

Metal Wine Racks

Metal Wine Racks with Wooden Case Storage Below

Metal VintageView are the most well-known metal wine racks. They are of good quality and come with their own assembly and installation instructions. The specific instructions included will depend on which type of metal wine racks you have chosen.

VintageView have racks that are wall mounted as well as types that are specifically designed to install away from a wall (free standing wine racks).

Instructions are different for wall-mounted racks, floor to ceiling mounted racks, and free-standing racks. The type of screws to use will also depend upon the wall material that you are mounting the racks onto.

Finding a Good Contractor or Wine Rack Installer for your Wine Cellar Project

Finding a contractor to build you a wine cellar in your location is not always an easy task. There are contractors out there that will tell you that they know how to build wine cellars and many of them may have built wine cellars in the past, but how do you know they installed them correctly?

Sadly, we often come across poorly installed wine racks and incorrectly built wine cellars.

We have repeatably come across situations where a contractor has put the vapor barrier on the wrong side of the insulation. Another insisted that the room needs ‘airflow’ from under the door. A contractor I spoke to thought he could vent the wall unit into a small closet with no rear ducting. All these contractors insisted that they had built and installed wine cellars before. Any wine cellar built this way will have future long-term problems that will require costly remediation work.

Applying the vapor barrier wrong can result in mold and mildew and warping of your walls and ceiling. A gap under your door allowing air flow will cause your refrigeration unit to run much more than it should and will run up your electric bill unnecessarily as well as wear out the unit sooner. It can also increase humidity that ultimately produces mold.

Venting into a small closet will not give you enough fresh air for the unit to work properly. The closet will build up heat, and your wine cellar will not cool to the correct temperature. This could also result in your cooling unit failing. Unfortunately, an improper installation will be the cause, and your warranty will not be valid.

Now to Get Started on Your Personal Residential Home Wine Cellar Project!

As Rachel for a Free 3D Wine Cellar Design with recommendations for equipment, structural guidance, and costings.