Spray Foam Insulation Used in Las Vegas Residential Custom Wine Cellar Construction

Why is spray foam insulation the best choice for wine cellar construction in Las Vegas homes?

Which type of spray foam insulation should be used in wine cellar construction in Las Vegas?

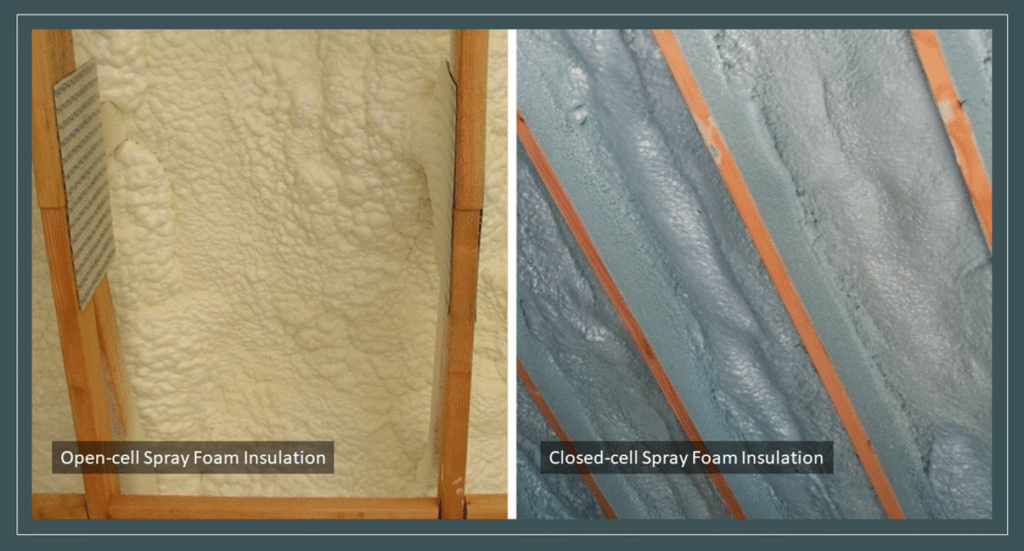

When looking at spray foam insulation, there are two types – open-cell or closed-cell.

Homeowners in Las Vegas will generally benefit from using spray foam insulation due to the extreme climate in the area. When building a home wine cellar, closed-cell spray foam insulation is the product of choice.

Both types of spray foam generally have their pros and cons. Both have unique qualities and costs that make them ideal for different types of projects.

Las Vegas enjoys an extreme climate; summer temperatures can stay well in excess of 100 degrees Fahrenheit for extended periods. Therefore, choosing the right form of insulation for your wine cellar in Las Vegas is a big deal.

What follows is a summary of the nature of spray foam insulation, along with an overview of the main differences between the two types of spray foam. This outline is designed to make it easy for homeowners in Las Vegas to understand and choose the best type of spray foam for their wine cellar project.

Open-cell Spray Foam Insulation

Open-cell spray foam is generally ideal for interior walls and raised floors in construction. While it is not quite as good an insulator as closed-cell, it is significantly less expensive than closed-cell insulation. Bear in mind though that it is a far superior insulator compared to traditional insulation materials.

Another key characteristic of open-cell spray foam is that it is a significantly better sound barrier than any other insulation option. This includes closed-cell spray foam. If reducing noise entering into or out of a room is your priority, open-cell spray foam insulation is your product of choice.

When applied between interior rooms, either in the floor or walls, one can enjoy solitude from anything else going on in adjacent rooms, including loud music and large home theater systems.

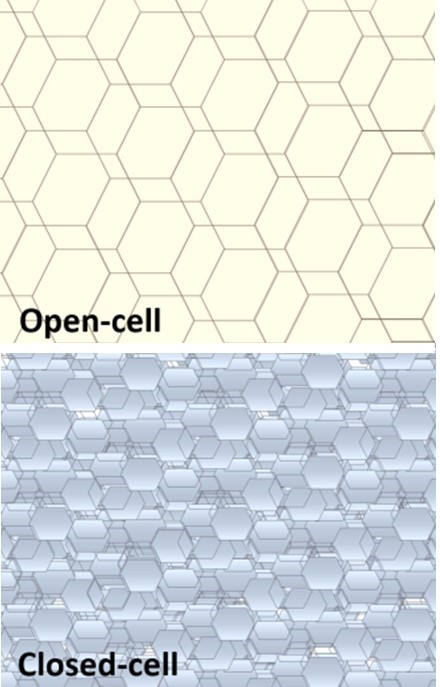

Technically speaking, open-cell foam has ½ lb. density compared to closed-cell foam which has a 2 lb. density. This simply means that it is better at absorbing vibrations, thus reducing the sound carried between rooms.

These characteristics mean that it is the product of choice for media rooms or any room where a quiet environment is a priority or where noise needs to be contained within the room. Bedrooms of teenage boys, or personal offices spaces can be an excellent use for this product!

Open-cell foam is also the foam of choice when injecting foam into existing walls. With some projects, it just doesn’t make sense to tear out old walls. In these cases, the preference is to inject foam into the spaces in-between the studs. Open-cell provides the only good option for insulating these properties.

Closed-cell Spray Foam Insulation

Closed-cell foam is ideal for exterior walls, crawl spaces, basements, attics, and flat roofs. Any application in fact where efficient temperature and weather insulation is the priority.

Closed-cell foam also has the added benefit that it can help improve structural strength and also acts as an inherent air barrier. This will reduce drafts and can help reduce intrusion into a structure by pollen, dust and other contaminants.

While open-cell spray foam is a better insulator compared to traditional insulation material, closed-cell spray foam insulation is significantly more effective than open-cell. If sheer temperature insulating effectiveness is your priority, closed-cell spray foam insulation should be your product of choice.

The more extreme the climate, the more important the insulation factor. Closed-cell spray foam insulation is, therefore, the best choice for home and commercial wine cellars — both small and big — in Las Vegas, Nevada.

Closed-cell Spray Foam Insulation – The Product of Choice for Custom Wine Cellar Construction

Closed-cell foam insulation has excellent resistance to water and low moisture vapor permeability. This means it can also act as a great vapor barrier in specialist applications such as residential home wine cellars.

Open-cell spray foam is generally ideal for interior walls and raised floors in construction. Closed-cell foam is ideal for exterior walls, crawl spaces, basements, attics, and flat roofs — any application in fact where efficient temperature and weather insulation is the priority.

Summary

Open-cell Spray Foam Insulation

- Better sound barrier

- Less expensive

- Great for interior wall remodels and retrofits

Closed-cell Spray Foam Insulation

- Better insulator

- Adds structural strength

- Acts as a vapor barrier

- The right product for exterior walls and wine cellars

More Useful Facts About Both Types of Spray Foam

Spray polyurethane foam insulation expands 120 times its initial volume and as a result fills cavities of pretty much any shape. This provides a continuous, protective air barrier that helps to minimize air leakage and air intrusion.

Improved energy efficiency is becoming a higher priority as we see energy costs increase, along with greater awareness of our environment, and the need to protect it.

The building envelope is the physical separator between the interior and exterior of a building. The selection of green building products that enable building envelopes to have enhanced insulation levels is becoming standard practice. Consumers are becoming increasingly aware of these issues. This fact, coupled with the recent availability of tax credits and energy rebates are driving the careful selection of energy efficient products such as spray foam insulation.

Technical Differences Between Open-cell vs. Closed-cell for Commercial Technicians, Designers, and Contractors

Open-cell Foam Insulation More Detail

Open-cell foam insulation is a thermal insulation material which is spray-applied. It has a half pound density and is non-structural. Ideally, it should be used for internal wall cavities, floor and ceiling assemblies, and in applications where sound insulation is a priority. Open-cell spray foam insulation has aged R-Values of 3.9 per inch.

Open-cell foam insulation provides a significant performance upgrade over conventional insulation products. Its application leads directly to improved energy efficiency and occupancy comfort. It provides a cleaner indoor environment along with greater noise reduction for commercial buildings and residences.

Open-cell spray foam technology is a cost-effective solution to improve the energy efficiency of a building.

Closed-cell Foam Insulation More Detail

One of the most efficient insulating materials commercially available, closed-cell spray foam insulation has aged R-Values above 6.0 per inch.

Properly installed closed-cell spray foam insulation frequently achieves energy savings as high as 45% over conventional insulation products.

In a typical building’s structural envelope, small imperfections such as cracks, holes, and gaps are often poorly sealed. Over time these lead to poor building performance or worse, moisture accumulation, allergen/pathogen growth, and in extreme cases structural failure.

The sealing capability and solid nature of closed-cell spray foam significantly inhibit moisture-driven intrusions. Just two inches of closed-cell spray polyurethane foam insulation will dramatically reduce air exfiltration and infiltration. It will also reduce conduction, convection, and reduce solar driven moisture within the building envelope.

The name “closed-cell” is based on the structure of the finished cell-based insulation material. There are literally millions of very small closed-cells within every cubic inch of the insulation material. These are filled with Enovate® 3000. Enovate® 3000 is a non-ozone depleting blowing agent.

This blowing agent, which is captured within the individual cells, contributes to the highly efficient insulating properties of the material. This “closed-cell” form of the spray foam product enables the material to become a highly efficient air barrier as well as having an inherent resistance to water and low moisture vapor permeability.

The density of closed-cell spray foam is approximately two pounds per cubic foot. This is what enables the foam to also provide both sheer and racking strength to wall assemblies in building applications.

In Conclusion

Homeowners in Las Vegas will generally benefit from using spray foam insulation due to the extreme climate in the area. When building a home wine cellar, closed-cell spray foam insulation is the product of choice.